Page 1 of 1

Proper Soldering Iron Tip to Solder the Pi to PCB

Posted: Wed Sep 13, 2017 2:24 pm

by Helder

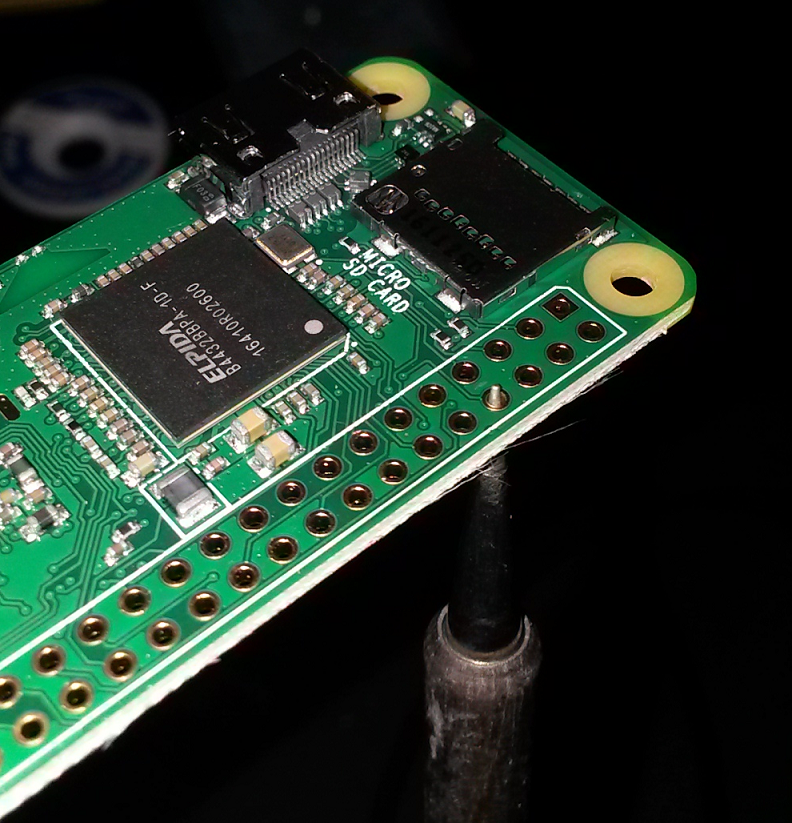

So I figure alot of people are not soldering things properly because they aren't using the proper tip and good solder so here is my recommendations and what I personally use.

If you have a Hakko or any of it's clones with temperature control then get a T18-C08 or 900M-T-0.8C tip, this has a small bezel at the tip and is narrow enough to solder through the GPIO to the PCB below.

Solder it's best to use thin solder like 0.015" or 0.030" and use 63/37 solder, leaded is best but lead free is ok too. This solder is nice and can be easy to control flow and leaves a nice shiny joint.

Iron temperature I use is about 320-340 degrees Celsius which will melt quickly and not cause damage if held on a pad for a little bit.

Hope this helps and anyone have something to add please do so.

Re: Proper Soldering Iron Tip to Solder the Pi to PCB

Posted: Wed Sep 13, 2017 2:54 pm

by moosepr

I normally tin the PCB pads with a tiny bit of solder, then a quick flash of flux, then clamp the pi in place (check orientation

)

I have also found that if you poke the solder into the pin hole before you touch with the iron, it seems to help get things flowing

Re: Proper Soldering Iron Tip to Solder the Pi to PCB

Posted: Wed Sep 13, 2017 4:23 pm

by dryja123

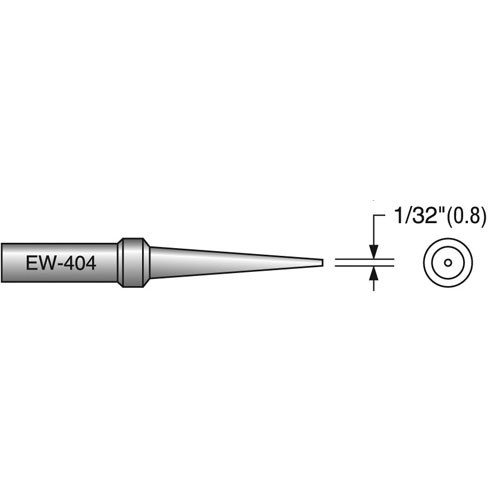

My iron is the Weller WES51 and I switch tips based on what I'm soldering. If I need to get into a GPIO, like in the case of the mintyPi, I use a long fine ETO tip. For everything I use a thicker conical tip like the ETA. I use .021 63/37 solder at 550 - 600 degrees fahrenheit.

- 112-682.01_s500_p1._V4c2b527a_.jpg (12.05 KiB) Viewed 9588 times

- Lead-Free-Replacement-tip-for-Weller-ETA-Size-1-6mm-Chisel-Used-with-weller-WESD51-WES51.jpg (143.83 KiB) Viewed 9588 times

Edit: Just wanted to add a little bit on moosepr's recommendation. When soldering wire to the board, like L1 and R1, tin the pad and tin your wire. It really doesn't take much effort to get the solid connection on those pads if you tin everything properly.

Re: Proper Soldering Iron Tip to Solder the Pi to PCB

Posted: Fri Sep 29, 2017 12:19 am

by ilike56k

Thanks, Helder! I'll have to get that tip.

The Tip I used (Which was a T18-BL) works, but has such a fine point that it isn't able to make very fast heat transfer at the very tippy-tip (at the PCB pads themselves).

- T18-BL.png (1.01 MiB) Viewed 9430 times

Re: Proper Soldering Iron Tip to Solder the Pi to PCB

Posted: Tue Nov 07, 2017 11:29 pm

by roddie

Thanks for the tips, Helder (pun intended) - I just ordered even more stuff from Amazon while I wait for the kit to show up.

Re: Proper Soldering Iron Tip to Solder the Pi to PCB

Posted: Mon Nov 20, 2017 7:16 pm

by EC2017

I also found that Maker Paste from Adafruit works to solder the Raspberry Pi to the buttons PCB.

Re: Proper Soldering Iron Tip to Solder the Pi to PCB

Posted: Mon Dec 18, 2017 8:28 pm

by Thealexbeast

Ive got a weller WES51, Is there a tip in this pack that is comparable?

https://www.amazon.com/Quality-replacem ... ering+tips

Re: Proper Soldering Iron Tip to Solder the Pi to PCB

Posted: Tue Dec 19, 2017 1:24 pm

by Helder

The 2nd and 3rd from the right look about right.

Re: Proper Soldering Iron Tip to Solder the Pi to PCB

Posted: Fri Dec 22, 2017 5:31 pm

by dryja123

Buy the Weller ETO tip for $6 and save yourself $24.

Re: Proper Soldering Iron Tip to Solder the Pi to PCB

Posted: Tue May 01, 2018 8:09 am

by djvoodoo

Helder wrote: ↑Wed Sep 13, 2017 2:24 pm

So I figure alot of people are not soldering things properly because they aren't using the proper tip and good solder so here is my recommendations and what I personally use.

If you have a Hakko or any of it's clones with temperature control then get a

T18-C08 or

900M-T-0.8C tip, this has a small bezel at the tip and is narrow enough to solder through the GPIO to the PCB below.

Solder it's best to use thin solder like 0.015" or 0.030" and use 63/37 solder, leaded is best but lead free is ok too. This solder is nice and can be easy to control flow and leaves a nice shiny joint.

Iron temperature I use is about 320-340 degrees Celsius which will melt quickly and not cause damage if held on a pad for a little bit.

Hope this helps and anyone have something to add please do so.

Great tip because i have been soldering way to hot lol

)

)